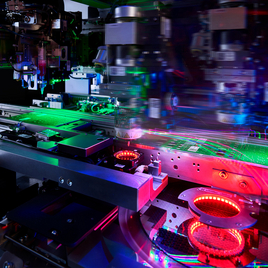

Datacon 2200 evo advanced

Accuracy & Flexibility for your mass production

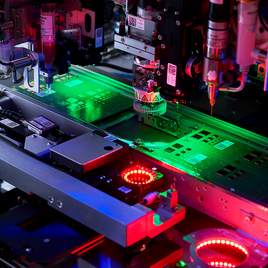

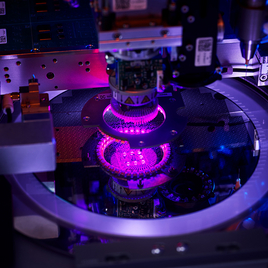

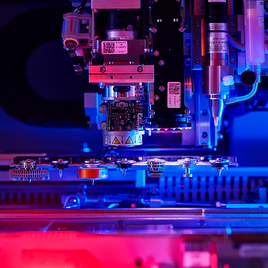

The new Datacon 2200 evo advanced is the latest edition in the well- established and field proven Multi Module Attach platform of Besi.With an all new gantry & controller system as well as a completely new vision and camera generation Datacon 2200 evo advanced offers superb 3μm placement accuracy while still focusing on your productivity and throughput requirements.

While significantly increasing the accuracy and placement capabilities the Datacon 2200 evo advanced does not forget its roots in the Multi Module Attach family. It is still offering the unbeaten flexibility as well as the full customization capability that the Datacon 2200 evo platform is so well known for.

Key Features

Accuracy

- ± 3µm @ 3s placement accuracy

- ± 0.07° @ 3s rotational accuracy

- New vision, optics and camera system

- Various configurable (FOV & resolution) set of cameras

- 3D & contactless height measurement options

Multi-chip

- Max. 14 different pick up tools / nozzles

- 5 eject tools

- 3 different epoxies / adhesive in a single pass

- Any flip chip / face up die combination

- Dual module for even higher productivity (option)

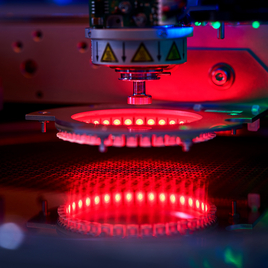

Bonding

- 0.5 - 25N closed loop bond-force

- 0-360° bond rotation

- Heated bond head (max. 450°C) (option)

- UV curing with up to 2,000mW/cm2 (365 / 405nm) (option)

Dispensing

- High-end auger pump

- Time pressure dispensing

- Piezo jetter valves

- Pin transfer

- Auto epoxy volume control

Specifications

Performance

- X/Y placement accuracy: ± 3 µm @ 3s

- Theta placement accuracy: ± 0.07° @ 3s

- Bond Force: 0.5N to 25N programmable

UPH

- Die attach: up to 7,000 UPH/module

- Flip Chip with dipping: up to 2,500 UPH/module

- Flip Chip without dipping: up to 3,200 UPH/module

Bond Heads

- Standard bond head 0° - 360° rotation

- Heated bond head up to 450°C (optional)

- UV Curing (365 nm & 405 nm)

Machine Dimensions

- LxDxH: 1,160 mm x 1,225 mm x 1,750 mm

- Weight: 1,300 kg

Statistics

- Uptime > 98 %

- Yield > 99.95 %

Wafer

- Die size Die Attach: 0.15 mm - 30 mm

- Die size Flip Chip: 0.5 mm - 30 mm

- Die thickness: >50 µm (thinner on request)

- Wafer size: 4" - 12" (SEMI M1)

- Frame size: FF070, FF105, FF108, FF123; automatic change (others on request)

Chip Trays

- Waffle pack / Gel-Pak® 2” x 2” and 4” x 4”

- JEDEC tray on request

Substrates and Carriers

- FR4, ceramic, BGA, flex, boat, lead frame, waffle pack

- Gel-Pak®, JEDEC tray, odd-shape substrates

- Substrate working range: 13” x 8” (325 mm x 200 mm)

Options

- Hardware: Open platform architecture for full customization

- Software: Single component tracking, CAD download, wafer mapping, substrate mapping, barcode scanner, datamatrix recognition and more