Fico Compact Line - P

The new Fico Compact Line - P (FCL-P) is the latest development in Trimming & Forming for power products. The FCL-P is the answer to the increasing demands on accuracy, Cpk and product traceability.

Increased press force

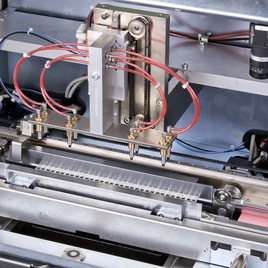

The FCL-P press has an advanced pollution control system that allows trouble free processing of preplated and interdigit leadframes. Each press has dedicated aspiration, with controlled high air flow speeds and a unique cyclone dust filter.

Different loaders and offloaders

A range of loader and offloader modules are available, ranging from magazines and cassettes to tray, bulk and tube. Short and controlled transport distances increase the performance of the FCL-P and at the same time prevent damage to your products.

More information?

Every FCL-P configuration is adapted to your product. Curious of what the FCL-P can do for you? Contact the Besi sales department for more information.

Key Features

Wide range of available modules

- Dual Stack Magazine Handler

- Control Unit

- Slotted Magazine Loader

- Power Press Module

- Gravity Tube Offloader

- Laser Marker

- Separator to Sorter

- Device Sorter

Dual Stack Magazine Handler

- Loader or offloader use

- Dual stack with automatic magazine rotation

- Auto ejection of rejected leadframes

- Servo motor controlled leadframe pusher

- Strip loading with vacuum pick-up head (ESD safe)

- Very short leadframe travel

- Smooth leadframe accelleration and transport

- Closed magazine bottom handling (option)

Vision Inspection

- Leadframe identification

- Leadframe orientation

- Bottom and/or Top inspection

- Large field of view

- High definition camera

- Stable construction

Power Press

- High press force: 50 kN (58 Joule)

- High airflow (vacuum and/or compressed air) in tool

- Exhaust system per press

- Easy tool exchange

- RFID tool recognition

- Output control from user interface

Tool

- High accuracy and reliability

- Sophisticated design for easy maintenance

- Different forming principles

- 225 mm tool width

- Enhanced pollution conttrol

Control unit

- Large 550mm touch screen user interface

- Customizable warning & status light

- Built in illumination

- Hand exhaust (option)

- SECS/GEM (option)

Slotted Magazine Loader

- Large 600mm cassette buffer

- Automatic magazine/leadframe centering

- Ionizer (option)

Gravity Tube Offloader

- Multi row processing

- Batch counting

- Pusher controlled filling

- Product orientation correction (option)

- Large tube stack

- Easy access

- Tube id check (option)

Specifications

Machine Dimensions

| Width | depends on the configuration |

|---|---|

| Depth | 950 mm |

| Height | 1,455 mm |

| Weight | depends on the configuration |

Product Handling Specifications

| Leadframe length | 150 - 300 mm |

|---|---|

| Leadframe width | 18 - 125 mm |

| Leadframe thickness | 0.1 - 2 mm |

| Package thickness | 0 - 10 mm |

Supply Requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power rating | depending on the configuration |

| Compressed air | 5 - 10 bar |

| Air consumption | dending on the configuration |

Speed and Noise level

| Speed | Max. 250 strokes per minute |

|---|---|

| Noise level | Lower than 75 dB(A) |

Available modules

| DSMH | Dual Stack Magazine Handler |

|---|---|

| CU | Control Unit |

| SML | Slotted Magazine Loader |

| PM | Press Module |

| GTO | Gravity Tube Offloader |

| LM | Laser Marker |

| S2S | Separator to Sorter |

| DS | Device Sorter |

Dual Stack Magazine Handler

| Magazine height | 150 - 600 mm |

|---|---|

| Magazine length | 150 - 306 mm |

| Magazine width | 25 - 131 mm |

| Magazine weight | max. 15 kg (including leadframes) |

Slotted Magazine Loader

| Magazine height | 100 - 240 mm |

|---|---|

| Magazine length | 170 - 300 mm |

| Magazine width | 25 - 160 mm |

Press Module

| Press force | 50 kN (58 Joule) |

|---|---|

| Tool width | 225 mm |

Gravity Tube Offloader

| Stack height | max. 600 mm |

|---|---|

| Fill width | max. 220 mm |

| Number of rows | 1 - 8 |

| Space between tubes (multi row) | 2.5 mm |

| Tube length | 150 - 600 mm |

| Tube width | 15 - 100 mm |

| Tube height | 5 - 25 mm |