Esec 2100 hSi

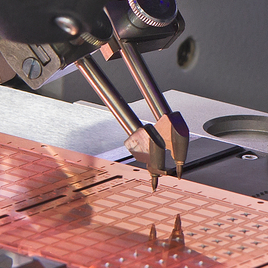

The new Esec 2100 hSi with its new Dual Dispensing Module enables an unmatched productivity and process quality. Process Accuracy is further improved with the new High Precision Bond Head as well as the High Resolution Vision Systems, which now also includes an Up Looking System. The Dispense Volume Control and the Low Contrast Kit bring process control to a yet unseen level. Last but not least, the Esec 2100 hSi introduces auto-optimizing pick up tool offset and dispense pressure after syringe change.

Key Features

Intelligence in Productivity

- Superior and proven 'light & rigid' P&P design

- High Performance P&P Y-axis with Liquid Cooling System

- Dual Dispensing Module with independent writing axes

- Dual 5 bar Pneumatic Dispense System Controller

- High Performance 4th Generation Vision System

- High Speed Production Mode with excellent accuracy

Intelligence in Accuracy

- High Resolution 4 Megapixel Vision Systems

- New High Resolution Up Looking Vision System

- High Precision Bond Head with highly accurate Theta-axis

- High Accuracy closed loop P&P Z-axis

- High Accuracy Production Modes

Intelligence in Process Control

- Low Contrast Object detection vision capability

- Three Dual Color Light Sources per camera

- Full High Definition (FHD) Graphical User Interface with multiple camera inspection images and viewers

- Sensor status overview of vacuum, air pressure and temperatures.

Intelligence in Automation

- Auto Adjusting Pick Up Tool offsets

- Auto Adjusting Dispense Pressure after syringe change

- Constant dispensing with Dispense Volume Control

- Auto Adjusting 2nd System on Dual Dispense Module

- Position Auto Correction of Die and Epoxy Placements

- Automatic Illumination Detection (vertical, indirect lights)

Specifications

Die Placement Accuracy

- >2 mm: 18 μm / 0.2° (3 σ) (high speed mode)

- >2 mm: 12 μm / 0.2° (3 σ) (accuracy mode)

- >2 mm: 10 μm / 0.15° (3 σ) (up looking vision)

- 0.5 - 2 mm: 20 μm / 1.0° (3 σ)

- MTBF: > 200 h

Productivity

- Up to 18500 UPH

Bond Process

- Bond force: 0.2 - 20 N

- Bond rotation: 360°

- Pre-bond/bond/post-bond heating: programmable, max. 200°C

Substrate Dimensions

- Width: 23 - 100 mm

- Length: 90 - 300 mm

- Thickness: 0.1 - 2.5 mm

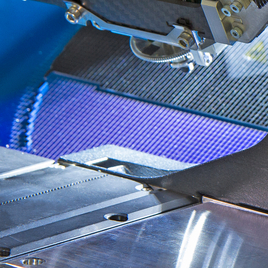

Wafer and Die Dimensions

- Wafer size: 4” - 12”

- Frame size: 8” - 12”

- Die size: 0.5 - 20 mm

- Die thickness: > 0.075 mm

Machine Dimensions

- Footprint: W x D x H: 1785 x 1448 x 1400 mm

- Weight: approx. 1400 kg / 3000 lb

Options

Substrate Handler

- Dual Input (MHIN and TOS)

- Magazine Handler Input (MHIN only)

- Raildownholder

- Motorized Downholder Disp/Bond

- Strip Marking Unit

- Strip Thickness Compensation

- Strip Handler 100 mm cold Flat

- Strip Handler 100 mm hot Flat

- Strip Handler 100 mm hot Rail

- Strip Handler 100 mm cold taped QFN

- Strip Handler 100 mm hot taped QFN

- Roll-Out Slippage Check

- SMEMA Link Input

- SMEMA Link Output

- Pick Strip from Box

Pick & Place

- Massflow Die Sensor

- High Precision Bond Head

- Liquid Cooling System

Die Ejector

- Dual Stage Die Ejector

Vision

- Bond Height Measurement System (BHMS)

- Dual Dispense Indirect Illumination 2 colors

- Bond Indirect Illumination 2 colors

- Dispense Vertical Indirect Illumination 2 colors

- Bond Vertical Indirect Illumination 2 colors

- Uplooking Vision

Automation

- Wafer Mapping inclusive Conversion

- Host Communication Interface

- E142 Strip Mapping

Dispense

- Device Z-height Control (DZHC-i)

Miscellaneous

- Uninterruptible Power Supply to PC

- Ionizer-Controlled Pick

- Ionizer-Controlled Bond

- Ionizer-Controlled Dispense

- Ionizer-Controlled WH Load Top

- Ionizer-Controlled WH Load Bottom

- Ionizer-Controlled Magazine Input

- Fine Filter Unit

- Fine Filter Unit with Air Particle Sensor