AMS-X

Leadframe molding re-invented

Besi has reinvented leadframe molding with the AMS-X. The increased market demand for power products and higher densities on larger leadframes asked for a new solution. With the AMS-X Besi has set a new benchmark in leadframe molding.

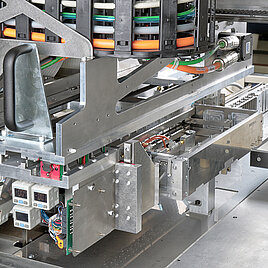

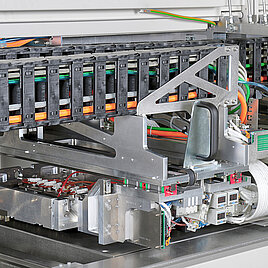

The AMS-X has newly developed plate presses. An extremely compact and rigid construction. To obtain a bleed free end product, each press has 4 clamp modules that ensure a high and even clamp force all around the product.

And with its new UX-design, the AMS-X is the most user friendly Besi molding system ever.

More information

Seeing is believing, so we are more than happy to give you a demonstration on a live system. Contact us today for more information.

Key Features

AMS-X

- Up to 30% higher output than competition

- Low Cost of Ownership - with latest state of the art technology

- Flash free - patented clamping mechanism

- High quality molding - full process control, dynamic clamping

- Low compound usage - unique runner design

- Suited for High Density and Power products

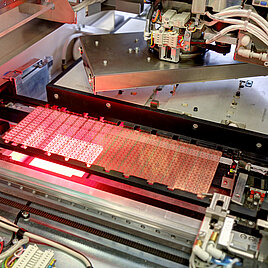

- Zero defect - 100% infeed and outfeed vision inspection possible

- Clean room class 1000

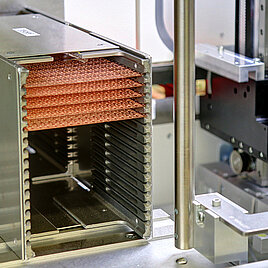

Slotted Magazine Loader

- High capacity

- Freely accessible

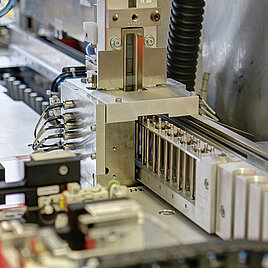

Infeed Module

- Strip orientation check

- Automatic orientation correction

- Strip pre-heating

Molding Press

- High clamp force

- Recipe controlled deep vacuum level

- Individually controlled 4-section clamp cylinders (optimal and equal substrate clamping)

- Even mold cap planarity

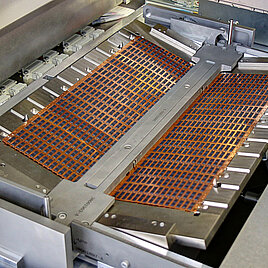

Outfeed module

- Integrated butterfly degating

- Large capacity central exhaust pump

- Double filter with blow back cleaning

FCL-X Press

- Sub-runner removal with standard Fico Compact Line - X press

- Compact tool

- High press force: 50 kN (6.6 Joule)

- Optical contactless safety pin detection

- High airflow (vacuum and/or compressed air) in tool

- Dedicated exhaust system

- Easy tool exchange

- RFID tool recognition

Dual Stack Magazine Handler

- Dual stack with automatic magazine rotation

- Servo motor controlled leadframe pusher

- Very short leadframe travel

- Closed magazine bottom handling (option)

Pellet feed

- Remote pellet feed (up to 40m)

- Pellet length check

- Pellet cooling

- Pellet age control

Specifications

Machine Dimensions*

| Width | 5,160 mm |

|---|---|

| Depth | 1,500 mm |

| Height | 1,800 mm |

| Weight | Approx. 9,500 kg |

* Base dimensions of the system, without protrusions like exhaust, hand grips and HMI support.

Leadframe Dimensions

| Width | Max. 125 mm |

|---|---|

| Length | Max. 300 mm |

| Thickness | Max. 10 mm |

Magazine Dimensions

| Width | 25 - 160 mm |

|---|---|

| Length | 170 - 300 mm |

| Height | 100 - 240 mm |

| Storage capacity | 600 mm |

Supply Requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power consumption | 14 kVA |

| Compressed air | 4.5 - 9 bar |

| Average air consumption | 5 m3/h at 6 bar |

| Factory exhaust | 2,000 m3/h |

Press and Mold Properties

| Max. clamp force | 1,800 kN (180 ton) |

|---|---|

| Max. mold opening | 150 mm |

| Max. transfer pressure | 15 MPa (150 bar) |

| Pellet diameter | 14, 14.3, 16 or 18 mm |

| Max. number of plungers | 12 |

| Max. cavity temperature difference | ± 2 ºC |