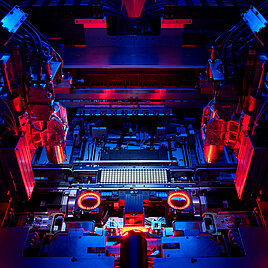

Datacon 8800 FC QUANTUM hS

Based on the industrial benchmark Datacon QUANTUM series, production speed was significantly increased compared to the successful Datacon FC QUANTUM advanced to offer an unprecedented Cost of Ownership. At the same time, no compromise on 4μm accuracy and process control was made to enable tool-to-tool repeatability at highest yield.

- Versatile High Speed Flip Chip Bonder

- Unique Quattro Concept

- Accuracy ± 4μm @ 3σ

- UPH up to 16,000

A Datacon QUANTUM system for your product

Seeing is believing, so we are more than happy to give you a demonstration on a live system in the Datacon QUANTUM range of flip chip equipment. Contact us today for more information.

Key Features

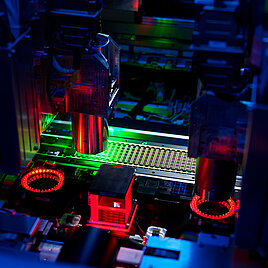

Extra Speed +100% Improved CoO

- Innovative "Quattro" multi nozzle concept

- Synchronous process steps

- High resolution large FoV camera systems

- Cluster adjust capability for bonding position alignment

Accuracy

- Proven accuracy 4μm @ 3s

- Enhanced 26MP camera system

- Optimized movements with Real Cross Influence

- New Matrix BMC 2.0

Full Yield Control

- Full Process & Production Control

- Superior usability with enhanced Pseudo X-Ray

- Fast Post Bond Inspection

- Individual Eject - Flip - and P&P - Toolinspection

- Chipping - / Die Crack detection

Ease of Use

- Minimal tooling quantity - fast device change over

- No die transfer shuttle - no intermediate steps

- Simple recovery handling

- Auto nozzle offset correction

Specifications

| X/Y placement accuracy | ± 4 µm @ 3 sigma |

|---|---|

| Bond force | 0.5N - 5N |

| Die size | 1 x 1 – 14 x 14mm |

| Die thickness | 0.05 - 2mm |

| Wafer size | 8" - 12" (on 8" or 12" wafer frames) |

| Substrate types | FR4, ceramic, BGA, strip, flex, boat, leadframe |

| Working range | 325 x 203mm |

| Flux film thickness | Various cavity plates available |

| Size | 1,600 x 1,983 x 1,940mm (W x D x H) (with dual monitor) |

| Weight | Ca. 2,000 kg |

| UPH | up to 16,000 (application dependant) |

| Vision system | WC/UC: FoV 29 x 29 mm, SC: FoV 16 x 16 mm |

Options

Substrate / Strip Handling

- Input/output buffer

- Magazine loader/unloader ML1

Vision system

- RGB lighting

- OCR for substrates

Software

- Functionality via existing standard SECS/GEM protocol

- Pseudo X-Ray

- Needle Hole Inspection

- Flip and P&P Tool Inspection

- Parameter provider

- Configurable user level

- Substrate/Strip/TU-Mapping (Semi S12, S14 in G84 and E142)

- Chipping Inspection

- Lot Management

- Restart Dialoge Region Selection

- Auto Illumination

- Custom Slow Travel Speed and Distance

- Single Component Tracking

- Cleartext Process Program (read only)

- Single Chip / Multiple Bond Positions

Component presentation

- Wafer stretcher (for 8" or 12" frames)

- Various stretch adapters (for metal and plastic frames)

- Wafer table rotation

Component handling system

- Upgraded ionizers for TS-input-area and Eject-area

- Pneumatic terminal

Others

- External vacuum pump

- Uninterruptable power supply

- ALPS Host computer