Fico AMS-LM

Molding is a process where micro chips are encapsulated in plastic. In line with the market trend toward SIP, exposed dies and more complex packages like dual side molding, Besi developed the large substrate molding machine Fico AMS-LM. The Fico AMS-LM can handle substrates of up to 102 x 280mm and can handle all current single and dual sided packages.

Large substrates allow a high board utilisation and in combination with deep vacuum, the unique clamp mechanism and the high output of the Fico AMS-LM, performance and yield increase significantly.

| Conventional | Fico AMS-LM |

|---|---|

| Standard substrates | Individually compensating clamp cylinders |

| Moving blocks | Modular mold design |

| Complex handling | 35% less moving parts |

| Large and heavy mold | Short conversion time |

| Long conversion time | Low cost PR-set |

| Expensive PR-set | Advanced process setup |

Key Features

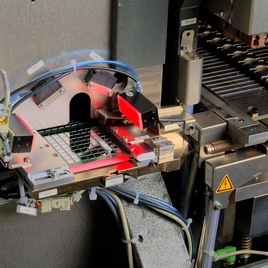

Cassette Handler

- High capacity

- Freely accessible

- Slot to slot copy

- Two or four deck version

- Bar code, 2D code and RFID reader (optional)

Vision

- Leadframe orientation check

- Mark inspection, bar code and 2D code check

- Optical Character Verification (OCV)

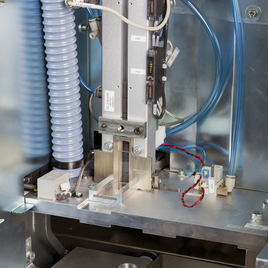

Leadframe Handler

- Automatic orientation correction

- Leadframe pre-heating

- Anti warpage leadframe cooling

- Air cushion transport

- Thin board handling

Molding Press

- High standard clamp force of 600kN (750kN optionally available)

- Recipe controlled deep vacuum level (vacuum as low as 1 torr)

- Recipe controlled venting mechanism

- Large, thick and thin, substrate molding

- Individually controlled clamp cylinders (optimal substrate thickness compensation)

- Dynamic Clamping Control (Selective molding & Flip Chip Exposed Die)

- Even mold cap planarity

- Topedge molding (no bleed with low viscosity compounds)

Pellet Supply

- Remote pellet feed (up to 40m)

- Pellet length check

- Pellet cooling

- Pellet age control

Specifications

Machine Dimensions

| Width | 3,145 mm |

|---|---|

| Depth | 1,652 mm |

| Height | 2,197 mm |

| Weight | Approx. 3,600 kg |

Leadframe Dimensions

| Width | 72 -102 mm |

|---|---|

| Length | 100 - 280 mm |

| Thickness | 0.1 - 1.5 mm |

| Height | Max. 2 mm |

Cassette Dimensions

| Width | 80 - 120 mm |

|---|---|

| Length | 180 - 300 mm |

| Height | 100 - 165 mm |

| Storage capacity | 800 mm |

Supply Requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power rating | 9 kVA |

| Compressed air | 5 - 10 bar |

| Average air consumption | 6 m3/h at 6 bar |

| Factory exhaust | 1000 m3/h at 50 Hz |

Equipment Performance

| Uptime | ≥ 98% |

|---|---|

| MTBF | ≥ 200 h for every MTTR of 1 h |

| MTBA | ≥ 3 h |

| MTTR | ≤ 1 h |

| MTTA | ≤ 3 min |

Press and Mold Properties

| Max. clamp force | 750 kN |

|---|---|

| Max. mold opening | 90 mm |

| Max. transfer pressure | 18 MPa |

| Pellet diameter | 11, 14 or 14.3 mm |

| Max. number of plungers | 10 |

| Max. cavity temperature difference | ± 2 ºC |

Downloads

PDF - 2 MB