Fico Molds

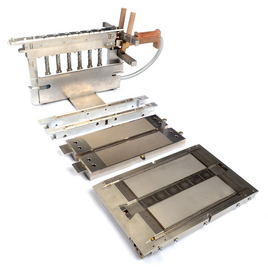

The original Fico molds guarantee high yields and a long lifetime of trouble free production. The quality of Fico molds is unsurpassed. All original Fico molds used on manual molding systems can unconditionally be used on automatic systems. For new product development Besi Netherlands provides a test mold base with easy and fast exchangeable package inserts, gate inserts and venting inserts.

Quotation?

Contact the Besi sales department for a dedicated quotation for a Fico mold for your system.

Key Features

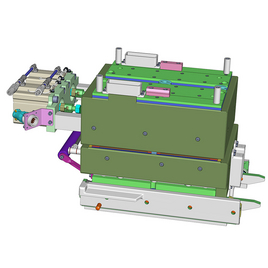

Wide Range of Mold Types

- Standard mold

- Vacuum mold

- Top and/or bottom foil mold

- Venting pin vacuum mold

- BGA mold with spring loaded board compensation

- BGA mold with automatic moving block spring compensation (patented)

- Top edge mold

Test Mold Base

- Exchangeable gate inserts

- Exchangeable package inserts

- Exchangeable venting inserts

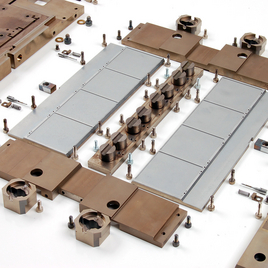

- Adjustable temperature zones

- Different mold materials

- Different mold coatings

- Cavity vacuum

- Board vacuum

- Ejector pin arrangement

Mold Design

- Mold flow simulation

- DOE (Design Of Experiment)

Process

- Mold design optimization

- Molding process window determination

- Suited for green compound

Vacuum Molding

- Board vacuum, prevents wire sagging

- Cavity vacuum, void and non-fill prevention

- Foil vacuum

Mold Properties

- Long cleaning interval

- Different mold coatings available

- Wide temperature range

- Automatic tool identification

- Easy product change over

- Low friction plunger – reliable end pressure

- Flip Chip molding – underfill and overflow molding in one molding process step (MSL level 2 @ 240ºC)

- Dynamic Temperature control – up to 30% higher output

Automatic Tool Identification

- Automatic tool identification (AMS-i and MMS-i)

- Mold shot counter

- Traceable mold cleaning history

- Automatic mold option settings

- Temperature settings storage per mold

- Automatic machine settings adjustment

- Fast and error free product change-over

Specifications

- Temperature range 150 – 260 ºC

- Clamp force range 10 – 900kN

- Leadframe width 45 – 75 mm

- Leadframe length 180 – 280 mm

- Leadframe thickness 0.1 – 1.5 mm

- Vacuum up to 50 mbar

Options

- Board vacuum

- Cavity vacuum

- Cavity vacuum control

- Foil assisted molding

- Top edge molding

- Bottom ejector pins

- Top ejector pins

- BGA board thickness compensation (patented)

- Flip Chip molding

- Adaptive clamping

- Dynamic Temperature Control