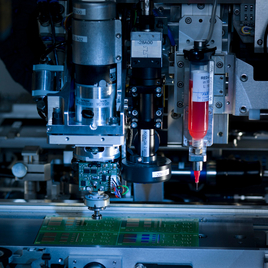

Datacon 2200 evo plus

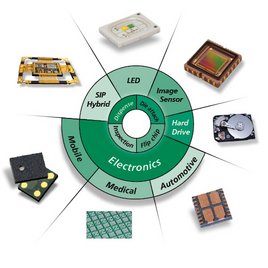

The Datacon 2200 evo plus die bonder for Multi Module Attach assembles all kinds of technologies on a tried-and-tested platform, enhanced with key features for higher bonding accuracy and lower cost-of-ownership.

Besides unbeaten flexibility and full customization possibilities, this evolutionary machine offers higher accuracy with long-term stability using a new camera system and thermal compensation algorithm, higher speed through a new image processing unit, and improved cleanroom capabilities.

Datacon 2200 evo goes PLUS!

-

PLUS accuracy

-

PLUS productivity

-

PLUS flexibility

-

Multi-chip capability

-

Flexibility for customizing

-

Open platform architecture

Key Features

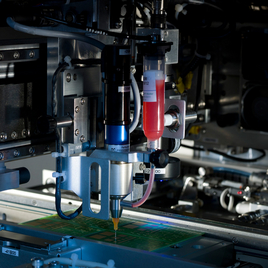

Integrated Dispenser

- Pressure/time (Musashi®), Auger, Jetter types available

- Epoxy stamping option

- Filled and unfilled epoxy, wide viscosity range

- Small footprint, low cost-of-ownership

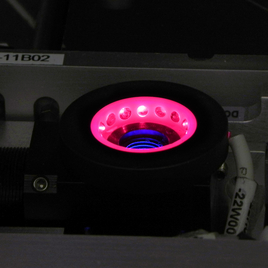

Vision Alignment

- New high-speed image processing unit

- Full alignment & bad mark search

- Pre-defined fiducial geometry & customized teaching

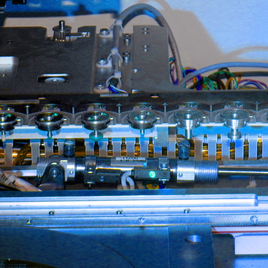

Automatic Wafer and Tool Changer

- Fully automatic cycle for multi-chip production

- Up to 7 pick & place tools (optionally 14), 5 eject tools

- Stamping tools and calibration tools possible

Pick & Place Head

- Die attach, flip chip and multi-chip in one machine

- Die pick from: wafer, waffle pack, Gel-Pak®, feeder

- Die place to: substrate, boat, carrier, PCB, leadframe, wafer

- Hot and cold processes supported: epoxy, soldering, thermo-compression, eutectic

Specifications

Performance

- X/Y placement accuracy: ± 7 µm @ 3s

- Theta placement accuracy: ± 0.10° @ 3s

- Bond Force: 0.5N to 75N programmable

UPH

- Die attach: up to 7,000 UPH/module

- Flip Chip with dipping: up to 2,500 UPH/module

- Flip Chip without dipping: up to 3,200 UPH/module

Bond Heads

- Standard bond head 0° - 360° rotation

- Heated bond head up to 450°C (optional)

- UV Curing (365 nm & 405 nm)

Machine Dimensions

- LxDxH: 1,160 mm x 1,225 mm x 1,750 mm

- Weight: 1,300 kg

Statistics

- Uptime > 98 %

- Yield > 99.95 %

Wafer

- Die size Die Attach: 0.15 mm - 30 mm

- Die size Flip Chip: 0.5 mm - 30 mm

- Die thickness: >50 µm (thinner on request)

- Wafer size: 4" - 12" (SEMI M1)

- Frame size: FF070, FF105, FF108, FF123; automatic change (others on request)

Chip Trays

- Waffle pack / Gel-Pak® 2” x 2” and 4” x 4”

- JEDEC tray on request

Substrates and Carriers

- FR4, ceramic, BGA, flex, boat, lead frame, waffle pack

- Gel-Pak®, JEDEC tray, odd-shape substrates

- Substrate working range: 13” x 8” (325 mm x 200 mm)

Options

- Hardware: Open platform architecture for full customization

- Software: Single component tracking, CAD download, wafer mapping, substrate mapping, barcode scanner, datamatrix recognition and more

Downloads

PDF - 929 KB