Fico Sawing Line

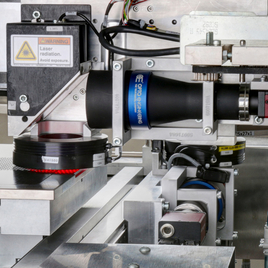

With the launch of the improved Fico Sawing Line (FSL), Besi initiates yet another era in singulation. The FSL is the only integrated singulation system on the market of a single solution provider.

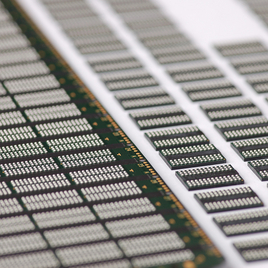

Singulation is a 4 step process where - from a large strip - individual products are sawn, cleaned, inspected and sorted. In the Fico Sawing Line, Besi has integrated all these process steps into one single machine. With its compact size the FSL has the highest output per square meter. The FSL carries out all process steps simultaneously using reliable vacuum on each single product, instead of tape. The unique and patented sawing method has the best scrap handling in the market and an unsurpassed accuracy. 100% inspection ensures that only perfect products leave the machine.

With the FSL, singulation is elevated to an art, the art of singulation.

More information?

Curious of what the Fico Sawing Line can do for you? Contact the Besi sales department for more information.

Key Features

Main improvement features

- Extreme warpage handling (best warpage handling in the market)

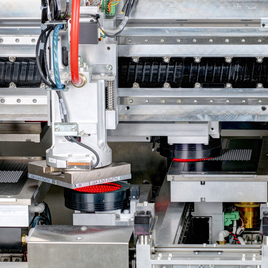

- Improved output with new 9-head sorting

- Improved accuracy - 25 μm offset/size accuray optionally available

- Step cut application (option)

High Output

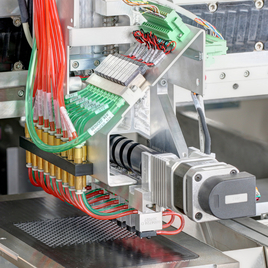

- Fully parallel processing with dedicated units

- Balanced throughput with optimal process performance

- Production output up to 34,000 UPH

Large Substrate Handling

- Capable of handling substrate sizes of up to 100 x 300 mm

- Fully prepared for future increase of high density substrate approach

Fast Conversion

- Fast & easy product conversion to different substrate & product size

- No tools required and completely automatic alignment of all product related parts

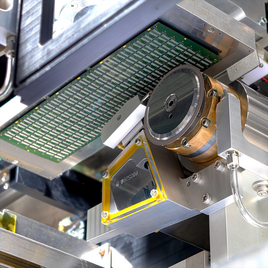

Upside Down Sawing

- Substrates and products are handled in a "live bug" (contacts down) state throughout the system

- End product is fixed from the top side

- Substrate is cut from below

- Cut scrap falls automatically into the waste bin

- Minimal risk of scrap hitting the sawing blade

High Accuracy

- All substrates are fully analyzed with the pre-alignment feature, operating in parallel with the sawing process (zero time loss)

- The sawing process is taking into account all specific substrate shape and geometry deviations

- Final package accuracy of ±50 μm at Cpk > 2.0 (6-sigma process control)

Features

- Automatic tray feeder

- Rework tray

- 3 reject bins

- 9 head product sorting

- Tape ring offloader (optional)

- 2.5 kW spindle power

- 3" blades (70 - 80 mm)

Specifications

Machine dimensions

| Width | 3657 mm |

|---|---|

| Depth | 1487 mm |

| Height | 1820 mm |

| Weight | approx. 3500 kg (empty) |

Leadframe dimensions

| Width | 28 - 100 mm |

|---|---|

| Length | 60 - 300 mm |

| Thickness | 6 mm |

| Product size | 1.6 x 1.6 - 50 x 50 mm |

Cassette dimensions

| Width | max. 120 mm |

|---|---|

| Length | max. 320 mm |

| Height | max. 240 mm |

| Buffer capacity | 640 mm |

Supply requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Current at 50 Hz | 28/25/14/13/12 A |

| Current at 60 Hz | 35/31/18/16/15 A |

| Footprint | 3.8 m2 |

| Ambient temperature | 15 - 40 oC |

| Water consumption | 500 l/h |

| Compressed air | 5 - 10 bar |

| Average air consumption | 5.5 m3/h at 5 bar |

| Factory exhaust | 300 m3/h at 50 Hz |

Equipment performance

| Uptime | ≥ 99% |

|---|---|

| MTBF | ≥ 200 h |

| MTBA | ≥ 4 h |

| Output | max. 34,000 UPH |

| Size accuracy | ±50 µm |

| Offset accuracy | ±50 µm |

| Capability / Cpk | >2.0 |

Downloads

PDF - 2 MB