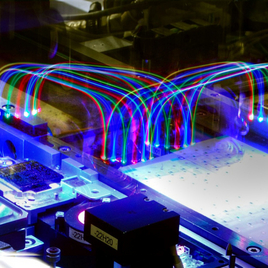

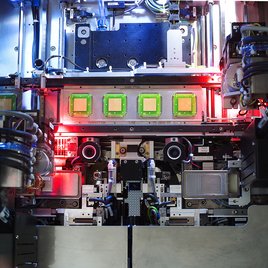

Datacon 8800 CHAMEO advanced

Highest Productivity for FO-WLP

As a new advanced packaging technology, Wafer-Level Fan-Out Packaging (WL-FOP) is a cost effective solution to address increasing demands for performance, form factor, and warpage control.

The Datacon 8800 CHAMEO advanced bonder raises a field proven platform concept to an advanced level. It is the perfect fit for chip attach of any WL-FOP process, supporting both face-down (flip mode) and face-up (non flip mode) package designs.

Key Features

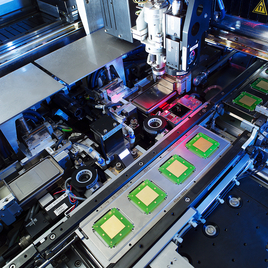

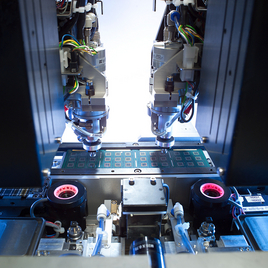

Multi-Chip – Combining Speed, Flexibility and Accuracy

- Multi-chip capability – Flexibility on smallest footprint

- Single pass is king – Improve your Cpk for multi-FC packages

- Waffle pack feeders – Extend your possibilities

- Extra Speed up to +40%

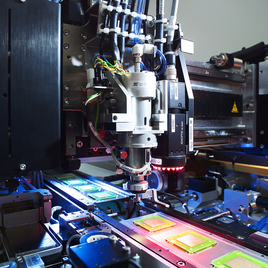

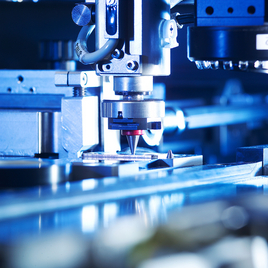

Enhanced Capabilities – Ready for the Future

- Thermo-compression – No limits for your applications

- Leadframe, strip, boat, wafer – No limits for your substrates

- Customized features – Exactly tailored for your process

- 300 mm / 340 mm Fan Out Wafer Level Packages (FO-WLP) Carrier

- Face-down & Face-up (recipe controlled)

- Clean room class ISO 5

- Foup load port

- Tape & Reel

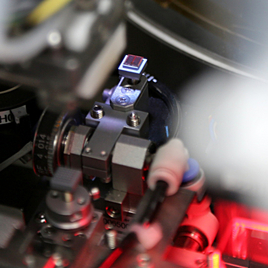

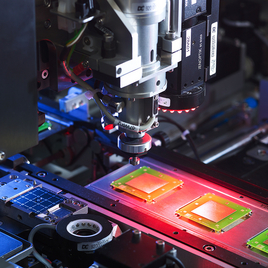

Highest Accuracy – Capturing Tomorrow’s Markets

- Highest Accuracy ± 5 µm / 3 µm @ 3 Sigma – For fine-pitch and TSV applications

- Local reflow – Mastering sophisticated assemblies

- Long-term stability – Securing high yield at high speed

Wafer Level Applications

- Fan-Out Wafer Level Packages – Highest performance for lowest cost

- Advanced Chip to Wafer – Cost effective dual die stacking

- Through Silicon Vias (TSV) – Entry ticket to the future

Specifications

| Local accuracy | ± 3µm @ 3 sigma |

|---|---|

| Global accuracy | ± 5µm @ 3 sigma |

| Vision system | 4Mpix, 6 x 6mm FOV for substrate / upwards camera 12 x 12mm for wafer camera |

| Strips, Boats, Panels | 340mm |

| C2W | 12" |

| Fluxer | option, various cavity plates available |

| Multi Chip | included |

| UPH (dipping process) | 6,000 |

| UPH (FO-WLP / no dipping) | up to 9,000 |

| Clean room class | ISO 5 (optionally) |

| Capability integrity | enhanced standard |

| Local reflow | not available |

| Lead time | 8 - 10 weeks |

| Bond force | 0.5 - 50N |

| Die size | 0.3 - 30mm |

| Die thickness | 50µm - 3mm, thinner on request |

| Footprint | 1,600 x 1,200 x 1,880mm (W x D x H) (with dual monitor) |

Options

Substrate / Strip handling

- Input / output buffer

- Magazine loader / unloader ML1

- FOUP load port

- Pre-heat station

Vision system

- RGB lighting

- OCR recognition for substrates "Golden eye" upward looking camera

Software

- Substrate/Strip/TU-Mapping (Semi S12, S14 in G84 and E142)

- Pseudo X-Ray

- Flip and P&P Tool Inspection

- Needle Hole Inspection

- Eject Tool Needle Inspection

- Eject Tool Cap Inspection

- Ejection System Live Cam

- SECS GEM Parameter Provider

- Wafermap Verification by Border Component

- Configure User Level

- Advanced Flux Imprint Check

- Chipping Inspection

- Auto Illumination

- Distributed Bonding

- Single Component Tracking

- Lot Management

- Complete bonding

- Custom slow travel speed/distance

- Measure component spacing

- Measuring component bench

- Fluxlevel detection

- Individual bond position offsets

- Advanced base calibration

Component presentation

- Wafer stretcher (for 8" or 12" frames)

- Various stretch adapters (for metal and plastic frames)

- Wafer table rotation

Component handling system

- Input TS ionizer

- HEPA filter system class ISO5

- Pneumatic terminal

- Dipping station (slidefluxer)

- Face-up

- Tape & Reel

- Temperature (constant)

Others

- External vacuum pump

- Uninterruptable power supply

- ALPS Host computer

Downloads

![]() Datacon 8800 CHAMEO advanced.pdf

Datacon 8800 CHAMEO advanced.pdf

PDF - 2 MB