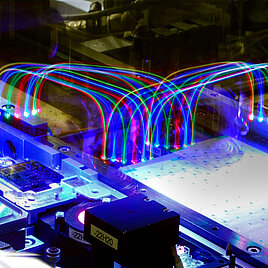

Datacon 8800 TC advanced

Thermo Compression bonding is the key technology for current 2.5D/3D C2S and C2W packaging, with TC-CUF as the currently established process for 3D memory applications.

The Datacon 8800 TC advanced sets the new benchmark based on the proven 8800 concept with total process control, advanced capabilities and unsurpassed production stability. With its unique and complete new Advanced Hardware architecture, unique 7-Axis Bond head and Advanced Process capabilities, the Datacon 8800 TC advanced is the essential tool of reference of current TSV applications.

The Datacon 8800 TC advanced:

- Ultra Fine Pitch Capability

- Enhanced Thermo Compression Bond Control

- 7-Axis Bond Head

- Highest Productivity on Smallest Footprint

Key features

Next Generation Control Platform

- New motion control - New hardware & software

- Enhanced trajectory control - Reduced latency times

- More computing power - Process variable tracing

7-Axis / 250N Bond Head

- 3 Actuators for positioning - X, Y, Theta

- 2 Axes for bond control - Z, W

- 2 Actuators for auto tilt setup - A, B

Advanced TC-CUF Yield Control

- Yield and down-time prevention caused by flux

- Trajectory controlled heating and cooling

- New thermal stress resistant tool holder - Tilt

- Accurate temperature calibration station

Optimized Tool Holder & Tool Hardware

- New tool holder design - Special improved electrical contact mechanism

- Fast maintenance

- New tool design - Improved heater temperature accuracy and optimized electrical contact material

Integrated Monitoring & Alarming

- Alarm window setup for any process variable

- Process variable monitoring against defined alarm window

- Escaping alarm window generates machine stop and alarm

- Monitoring results available via SECS/GEM

Temperature Calibration Station

- Enhanced tool to tool repeatability

- In-situ temperature check - 20 to 240 °C within ±1 °C

- Portable sensor - Move from machine to machine

Tool to Tool Repeatability

- Recipe portability

- Separation of machine and recipe parameters

- Auto calibration - Consistantly calibrated tools

- Portable alarm windows

Specifications

Performance

| X/Y placement accuracy | ± 2 µm @ 3 sigma |

|---|---|

| Accuracy self check | Single BMC kit |

| Output | up to 1,000 UPH |

| Number of bond heads | 2 |

| 7-axis TC bond head | -4° - 4° rotation |

| Tool heating | up to 420 °C |

| Ramping speed | + 200 °C/s (Heating) - 100 °C/s (Cooling) |

| Temperature uniformity | ± 5 °C |

| Interface temperature monitoring | Integrated measurement |

| Bond force | 3 - 250 N (full UPH) |

| Bond control | Force / Height / Both combined |

| Tool flatness | ± 1 µm |

| Co-planarity | ± 2 µm @ 10 mm |

| Co-planarity set-up | Automatic |

| Footprint | 1,600 x 1,200 x 1,880mm (with dual monitor) |

| Uptime | > 95% |

Substrate & Carriers

| C2S - Strips | max. 260 x 125 mm |

|---|---|

| C2S - Boats/Carriers | max. 260 x 125 mm |

| C2W - Wafers | max. 12" (300 mm) |

| C2W - Loading | Manual / FOUP on request (option) |

| Substrate heating | max. 200 °C ± 2.5% |

Components

| Die size | 2 - 16 mm |

|---|---|

| Die thickness | 50µm - 3mm, thinner on request |

| Wafer size | 8" - 12" (200 - 300 mm) |

| Frame size | 9" - 15" (125 - 375 mm) |

Multi-chip Capability

| Teaching | Camera view |

|---|---|

| Multi-chip modes | Stacked die or Side-by-side |

| Wafer change | Automatic (up to 25 types per cassette) |

| Pick & Place tool change | Manual |

| Ejector tool change | Automatic (up to 3 sizes) |

| Bond profiles | Individual bond profiles per stack layer |

Component Handling

| Flip chip unit | Pick-up of the component from wafer, 180° rotation of the flip arm and presentation to the bond head |

|---|---|

| Wafer pre-rotation | 0° - 280° |

| Slide fluxer | Optional |

| Cassettes | 1 |

| Cassette size | up to 25 film frames per cassette |

Substrate Handling

| Substrate & carrier transport | Gripper based with vacuum cups |

|---|---|

| Wafer transport | Robot handling (from dual FOUP port on request) |

| I/O buffer | Flat belt system, inline (SMEMA) or stand-alone possible |

| I/O Elevator type | Programmable lift systems for one magazine |

| I/O Magazine size | Various (on request) |

Tool system

| Bond tools | Integrated heater / cooler and temperature sensor |

|---|---|

| Single chip ejector | For one configured ejector tool |

| Multi chip ejector | Automatic quick changing carousel system, max. 3 ejector tools |

Vision system

| Field of View | Wafer camera: 12 x 12 mm Substrate camera: 2.0 x 1.6 mm Up-looking camera: 2.0 x 1.6 mm |

|---|---|

| Illumination | Programmable RGB lighting (4 different colors) |

| Image recognition methods | Circle search, edge search, bump search, feature matching, structure search, epoxy inspection, contour inspection, datamatrix recognition, ... |

Computer and MMI system

| Operating system | Linux |

|---|---|

| User interface (GUI) | User-friendly graphical user interface with pull-down menus |

| Monitor | 2x 19" flat screen |

| Data storage | HDD, USB |

| Data transfer | FTP via TCP/IP network, SECS/GEM |

| Interface | SMEMA 1.2, SECS-II (GEM compliant) |

Standard software

| Features | Post -bond inspection, Z-positional bonding, Auto-calibration |

|---|---|

| Programming wizards | Step-by-step guided programming with graphical support for e.g. product, substrate, component, epoxy |

Options

Flux Application

- Flux film thickness: Cavity plates from 5 μm – 200 μm

- Viscosity range: 2,800 cps – 110,000 cps

Hardware

- Open platform architecture for full customization

Software

- Single component tracking

- Wafer mapping

- Barcode scanner

- Data matrix recognition

- Substrate/Strip/TU-Mapping (Semi S12, S14 in G84 and E142)

- Pseudo X-Ray

- Flip and P&P Tool Inspection

- Needle Hole Inspection

- Eject Tool Needle Inspection

- Eject Tool Cap Inspection

- Ejection System Live Cam

- SECS GEM Parameter Provider

- Wafermap Verification by Border Component

- Configure User Level

- Advanced Flux Imprint Check

- Chipping Inspection

- Auto Illumination

- Distributed Bonding

- Lot Management

- Complete bonding

- Custom Slow Travel speed /distance

- Measure component spacing

- Individual bond position offsets

- Fluxlevel detection

- Parameter provider